WHY THESE PRODUCTS?

Targeting and removing specific pollutants can be challenging. This is why we have partnered with the best and brightest stormwater quality experts in the country to provide a suite of specialized pollutant removal systems for Total Suspended Solids, Nitrogen, Phosphorus, Heavy Metals, Bacteria and more.

Our Pollutant Removal Filter Products

Helix

High-Flow Filter System

Next Generation, High-Flow, Stormwater Filter

The Helix is a next generation, high-flow, stormwater filter that can be housed in a vault or installed directly into an outfall pipe. When applied with antimicrobial media it can treat bacteria at a large scale.

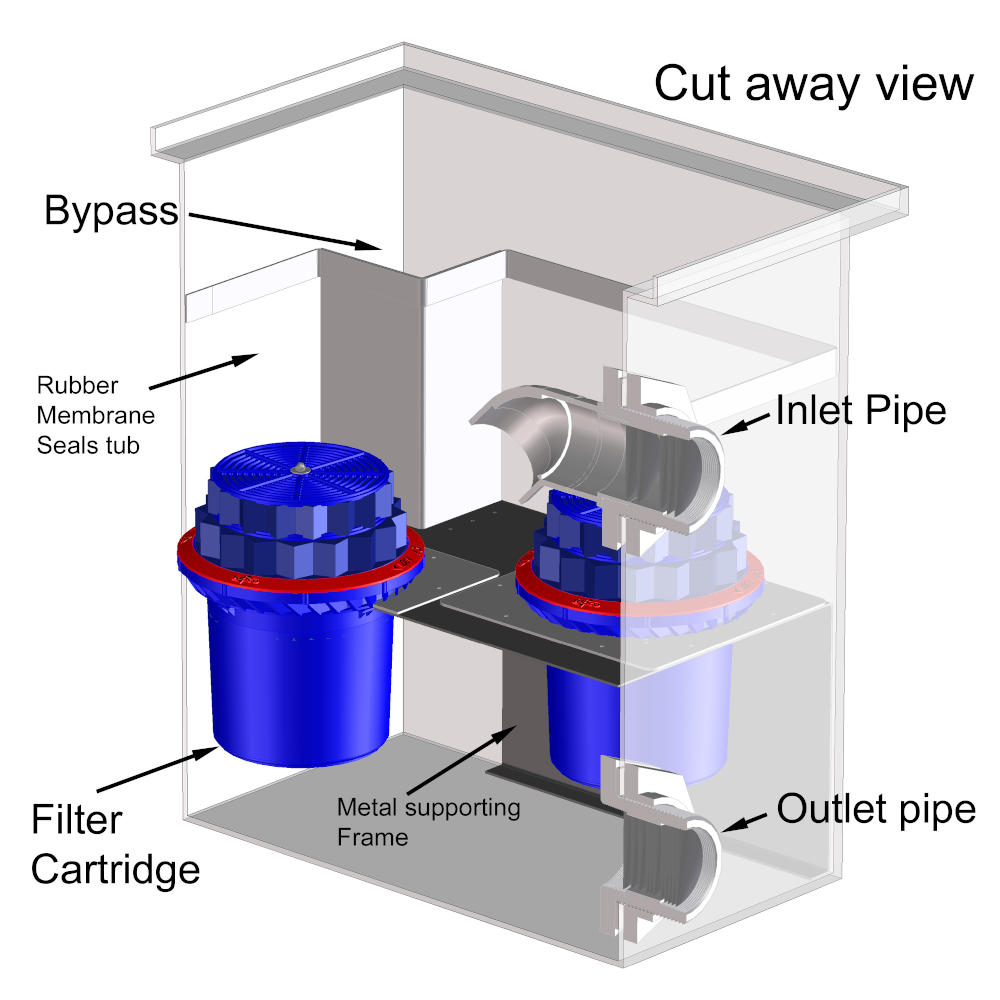

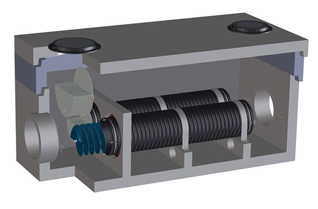

Effective Two-Step Treatment Process

The Helix vault is has a two-step treatment process that incorporates an inlet chamber used to reduce clogging from sediments and debris, and a secondary treatment chamber that houses Helix’s filter elements. Coarse pollutants contained in the stormwater runoff is captured upfront – this sediment separator treats water at higher flow rates and can be serviced from the surface level with a Vac truck. The pre-treated water exiting the first chamber will keep the Helix filters cleaner, helping maintain flow rates and effectiveness while minimizing the need for maintenance.

Patented Helix Filter Technology

The horizontal filter column design provides great flexibility for selecting the appropriate filter length and diameter for a given flow rate. The Helix elements inside the column(s) function as a multiple disk filter providing tremendous surface area for treatment. The spiral form offers multiple flow paths through the filter which allows the system to maintain a high flow rate while significantly reducing clogging potential.

The horizontal filter column design provides great flexibility for selecting the appropriate filter length and diameter for a given flow rate. The Helix elements inside the column(s) function as a multiple disk filter providing tremendous surface area for treatment. The spiral form offers multiple flow paths through the filter which allows the system to maintain a high flow rate while significantly reducing clogging potential.

Each Helix filter column has a designed treatment flow rate of approximately 3 cubic feet/sec. Helix filters are offered as single, double and triple column systems. Filter cartridges are replaceable and can be accessed though a standard 36″ diameter manhole provided in the vault.

Also, each Helix filter column is supplied with an inlet diffuser which is designed to keep any debris that passes through the sediment separator out of the filter column. Of course as a final precaution, each Helix also incorporates a full overflow bypass.

SUPPORT MATERIAL

CONTACT US

DownSpout

Treat Particulates and Soluble Pollutants

The Fabco DownSpout Filter is designed to treat particulates and soluble pollutants contained in runoff water from roof tops. This product is perfect for industrial facilities that deal with waste treatment, metal recycling etc. Read more about the specific applications below.

Applications

Heavy Metals: Stormwater can react with metal roofs, metal components or roof mounted equipment releasing soluble metals, such as zinc, copper, lead and aluminum in to the environment. Studies have shown that zinc concentrations in rooftop runoff are substantially higher than those found in rainwater. Elevated levels of zinc in soils can lead to phytotoxicity (poisoning of plant life).

Pathogens: Birds, insects, and small mammals deposit fecal matter on rooftops and in gutters, contributing bacteria and pathogens to runoff.

Hydrocarbons: Polycyclic aromatic hydrocarbons (PAHs), dust and particulate matter from vehicle exhaust and the burning of fossil fuels can collect on roof surfaces, producing elevated PAH levels in runoff.

System Overview

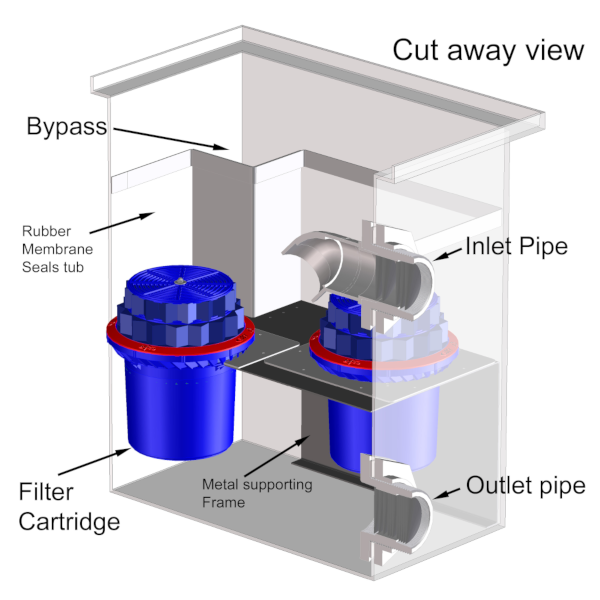

- Large freestanding filter enclosure offers multiple above ground installation and mounting options

- Constructed from 300 series Stainless Steel – powder coated on exterior surfaces only

- Overall dimensions: 24 1/8” W x 33 ½”L x 40 3/4” high (standard)

- Hinged door panel opens away from the building side and features a latch for secure retention and rubber bumpers to protect cabinet

- Stainless Steel mounting surface provides “Twist-Lok” retention and a tight seal

- 4” PVC inlet/Outlet pipes (standard)

- Clean out port provided at the bottom of the chamber for cleanout and dewatering

- Dual cartridge filter flow rate can vary depending on cartridge type selected from 120 to 520 gpm

- Internal debris storage capacity is 5.0 ft3

- Built in high flow bypass is capable of passing 460.0 gpm (1.0 cfs)

- Internal debris screen separates inlet side of treatment chamber from the filter cartridge area – coarse screen pre-filters the water helping to maintain treatment flow rate