While automation is not new, stormwater automation is only in its infancy. It’s no wonder Construction EcoServices, a leader in Stormwater Innovation has been involved in many of the first stormwater automation projects. From managing subsurface underground detention / rainwater harvesting systems through weather predictive technology to creating automated settling ponds for stormwater quality, Construction EcoServices is once again on the bleeding edge of stormwater management. The future of stormwater is automated, through controls, sensors and telemetry, we will soon change the way stormwater is managed. A move from passive control to active control is on the horizon.

Our Automated Stormwater Management Products:

- smartPONDbw (Batch Weir)

- smartPONDbv (Batch Valve)

smartPONDbw for Automated Detention & Drainage

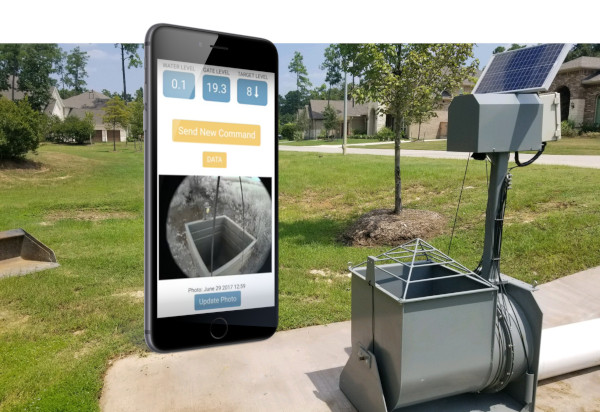

Our weather is constantly changing, yet our stormwater controls remain the same. smartPONDbw takes passive stormwater controls and gives them brains, allowing for either pre-programmed stormwater pond management that actively measures and releases stormwater to match your regulatory regime, as well as application-based real time control that allows you to retain or release water at the tip of your fingers.

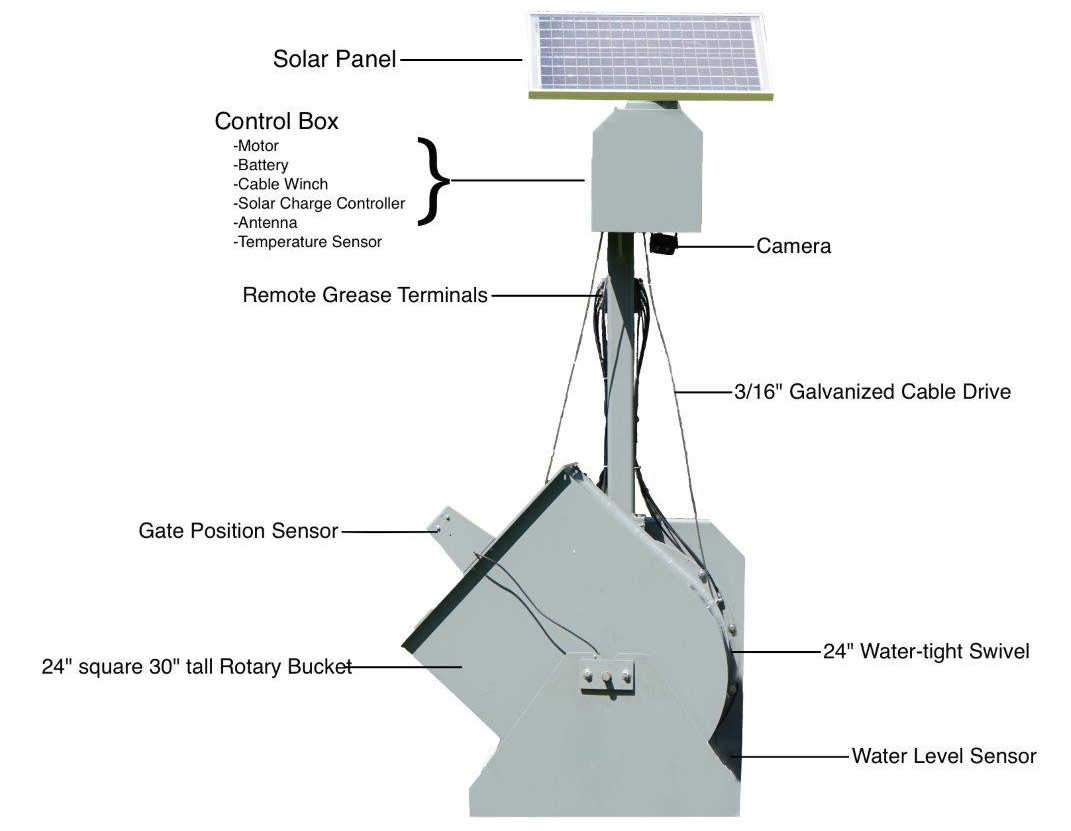

Through the use of an innovative, automated rotating skimmer, an entire watershed can be controlled automatically or at the push of a button. Routine inspections can be monitored remotely with the smartPOND onboard camera, giving owners and 3rd party operators instant feedback on the condition of the system. Automated processes also make users aware of upcoming system maintenance needs, sending alerts to users’ smartphones/e-mail with advance notice of battery, solar panel or other component maintenance needs within a predetermined time frame. smartPONDbw is the intelligent choice for your automated detention, retention or rainwater harvesting system.

smartPONDbw for Automated Batch Detention

A batch detention basin is an extended detention basin that is primarily used to remove particulate pollutants and to mimic predevelopment hydrology. Batch detention basins have superior water quality performance over traditional sedimentation/sand filters and achieve a total suspended solids (TSS) removal efficiency of 91%.

- 91% TSS removal = 20% less volume = smaller basin

- No splitter box

- No gabions

- No sand

- No perforated pipes

Finally, a prepackaged batch detention solution is here.

smartPONDbw is a prepackaged, easy to install, automated water level control valve that regulates stormwater depth and meets batch detention requirements per the Texas Commission on Environmental Quality (TCEQ) Edwards Aquifer Protection Plan (EAPP).

smartPONDbw functions by rotating 90 degrees to open and close a rotary weir that is connected to an outfall pipe up to 24-inches in diameter. It is pre-programmed to hold water for 12 hours and then rotates slowly over a 48-hour period to drain the batch detention pond completely. Once empty, the bucket returns to its upright and closed position in anticipation of the next rainfall event. Fundamentally, smartBATCH allows TSS to settle out of the detained water body, the releases the cleanest water from the top of the pond.

Monitoring and full system controls at the tip of your fingers

smartPONDbw takes passive stormwater controls and gives them brains, allowing for both pre-programmed stormwater quality management and application-based real-time controls. Routine inspections can be monitored remotely with the smartPONDbw onboard camera, giving owners and operators instant feedback. Automated processes also make users aware of upcoming system maintenance needs by sending alerts to a smartphone or an email address. All components are modular and can easily be replaced by the user.

CONTACT US

Why Do We Recommend This Product?

“No question about it, smartPOND and other automated stormwater solutions are the future – and the future really is now. Using automation to manage the retention, detention and drainage of watersheds offers a world of new benefits.”

David Batts

Stormwater Systems Director

SUPPORT MATERIAL

BENEFITS

- Greater efficiency over sand filters

- Real time maintenance alerts

- Real time data water level, gate position, temperature & more

- Tough and versatile design

- Total Suspended Solid (TSS) removal = 91%

- Maintains settling pond benefits while dewatering

- Meets Edward’s Aquifer Protection Plan Batch Detection Requirements

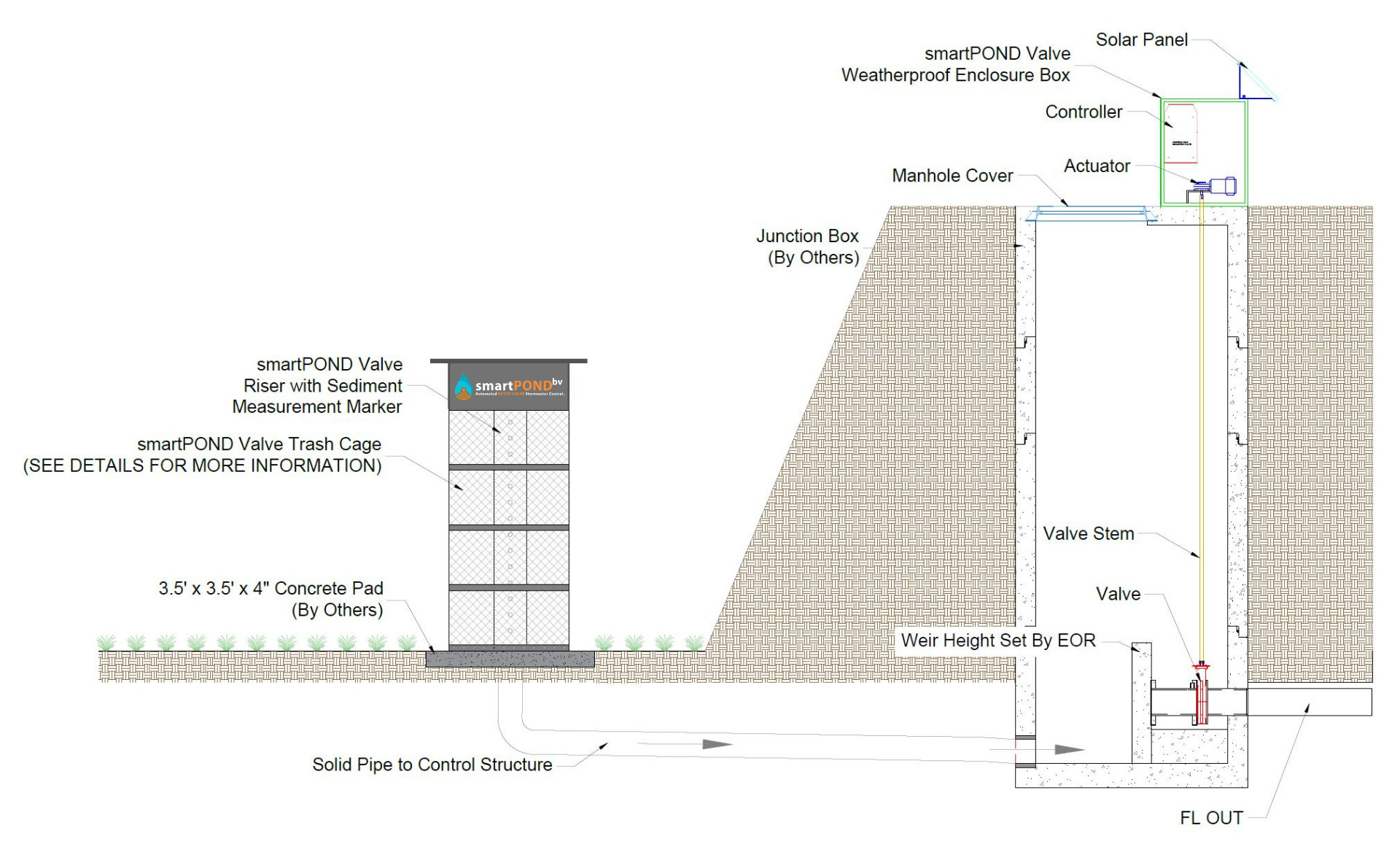

smartPONDbv for Automated Valve Detention

The smartPONDbv was designed with the property owner’s budget in mind. It’s all-in-one design and specification makes engineering simple by providing a complete detail kit that requires no electrical or low voltage design, no complicated parts list, or complex drainage calculation. For the contractor, smartPONDbv is plug-and play. Simply connect the smartPONDbv perforated riser and trash cage to the inflow pipe. Then connect the nyoplast housing to the outfall pipe and backfill. Finally, secure the control box to valve stem and activate with the flip of a switch. For the owner, maintenance alerts are automatically sent to your cell phone to let you know when the system isn’t functioning properly, eliminating the need for costly inspections.

The smartPONDbv is backed by a one-year warranty and includes a year of monitoring. Extended warranties are available.

BENEFITS

- Achieves greater efficiency over sand filters (91% TSS removal)

- Maintains settling pond benefits while dewatering

- Advance or real-time programming of dewatering events

- Real time data available – water levels, gate position, temperature, photos, maintenance records and more

- Tough and versatile design

- 2-year warranty

- 1-year smartBATCH maintenance and maintenance alert notifications

- Simple Installation

- Plug and Play Design = Completely Self Contained

- Custom 30” Drain Basin

- Valve Quick Release Design for Simplified Valve Maintenance

- Valve Spool keeps all components out of the pond

- Durable, American Made

- Self Monitoring & Includes First Year Comes with Maintenance Alerts

- Completely Offline

- Simple to Maintain

Why Do We Recommend This Product?

“smartPOND is the ultimate solution for the batch detention BMP. Ease of specification and installation make it a true “plug-and-play” option. There is no other product on the market that can provide the real time data and analytics that smartPOND offers.”

Dan Conaway

Territory Manager: Central Texas